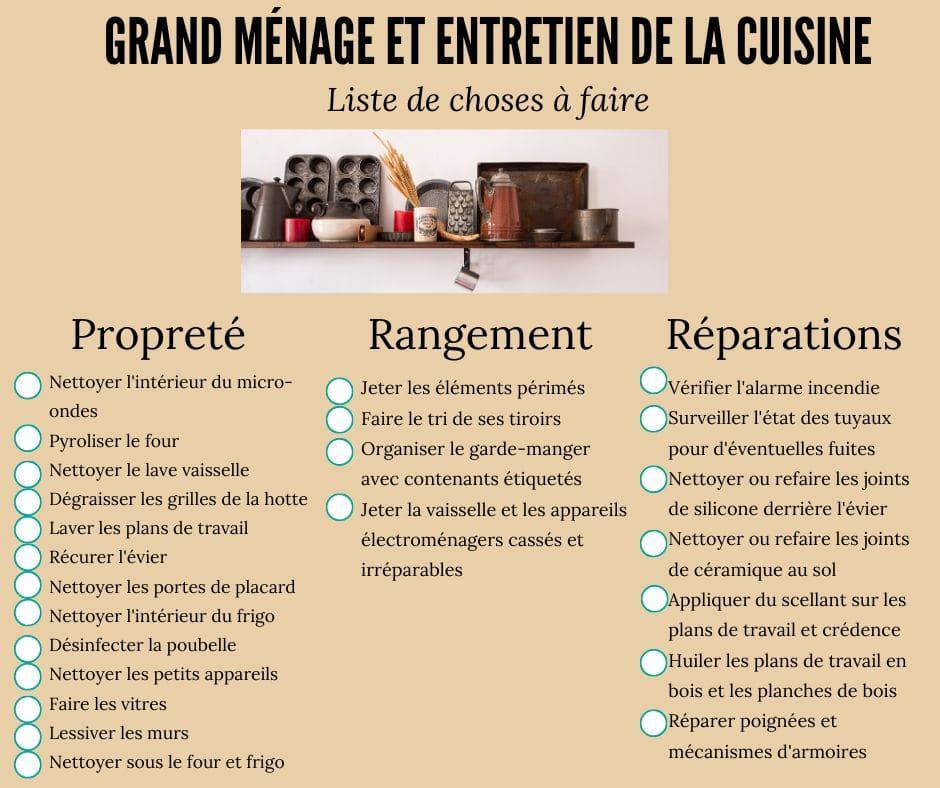

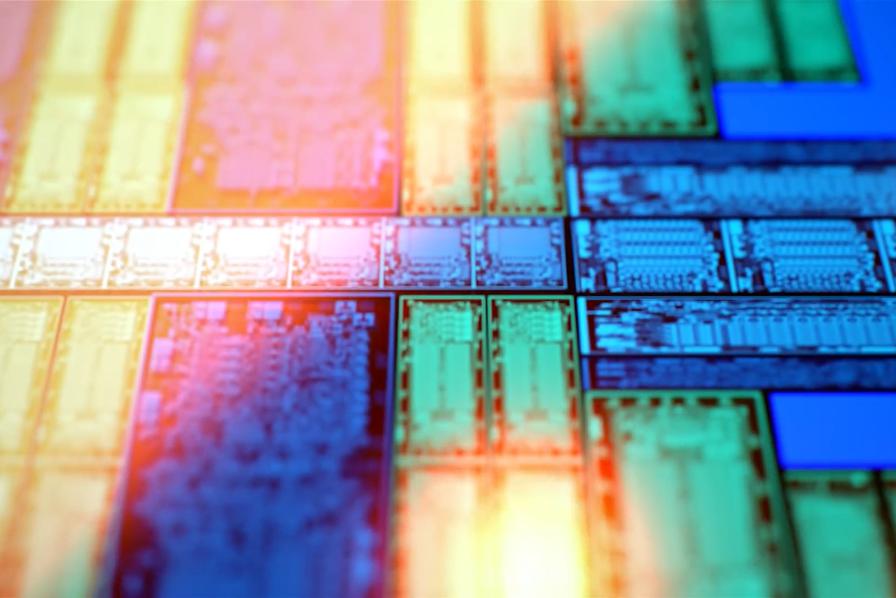

The Russian-Ukrainian crisis puts the global chip industry under high tension. Experts point to the risk, in the event of an armed conflict, of a sudden disruption of supply for certain raw materials, mainly from Ukraine and Russia. The US administration has sounded the alarm and invited US semiconductor manufacturers to anticipate by listing alternative sources of supply.

The risk concerns two substances in particular: neon and palladium. Neon is an inert gas used in the Excimer laser of deep UV lithography equipment. It is involved in a key manufacturing step, photolithography, which consists of creating the circuit patterns by exposure to UV radiation of 248 or 193 nanometers. This technology is essential for engravings from 180 to 10 nanometers, which represent the overwhelming majority of production today.

YOURINDICES

source1.0878 +0.48

April 14, 2022

Us dollar (USD) - daily

$USD/€

6.932 +0.55

April 14, 2022

Chinese Yuan (CNY) - Daily

¥ CNY/€

111.7 +2.68

April 14, 2022

Brent oil futures contract close to maturity

$USD/barrel

All indicesPrices multiplied by 10

According to the Omdia firm, Ukraine supplies more than 70% of the neon gas consumed in the world through companies such as Iceblick, Ingas or Cryoin. The chip industry consumes only a very small part of it. But this gas is unavoidable and cannot be replaced by another. If the supply is cut, there will be an impact on the semiconductor industry.

TrendForce, however, puts the magnitude of the threat into perspective. Given the stocks available at chipmakers and the regional dimension of the problem, he does not foresee a shutdown of semiconductor factories after the interruption of Ukrainian supplies. But he foresees a rise in neon gas prices which would increase the cost of producing the chips. Omdia recalls the price paid by the industry in 2015-2016 after the 2014 annexation of Crimea by Russia. This crisis caused a great shortage of neon which led to a multiplication of the price of this gas by a factor of 10.

Retaliation from Russia

Palladium is used at the end of the manufacturing process in the packaging of chips. Russia is the world's main supplier. The United States fears that in the event of a conflict, Russia will respond to Western sanctions by stopping its deliveries.

“Making semiconductors is incredibly difficult and expensive,” says Omdia. Whether it's pushing the laws of physics or having to rely on rare and hard-to-find substances, the work of Samsung, Intel, Texas Instruments or GlobalFoundries has never been more complicated. Unfortunately, the prospect of war in Ukraine is very bad news for the semiconductor industry and could significantly worsen the current chip shortage.”

Selectedfor you